The Rotary Multi-Station Ultrasonic Welding System with Unloading Unit is an advanced automated welding solution designed for high-volume, precision plastic welding applications.

By integrating rotary indexing technology, multi-station ultrasonic welding, and automatic unloading, this system significantly improves production efficiency, consistency, and labor cost control.

This operation video demonstrates the rotary multi-station ultrasonic welding system in action,

showing indexed rotary table motion, simultaneous multi-station welding, automatic unloading,

and precise control under PLC + HMI system.

● Multi-Station Rotary Design for Continuous Production

The rotary table enables multiple welding stations to operate simultaneously, allowing loading,

welding, cooling, and unloading processes to run in parallel.

This design greatly increases output compared with single-station ultrasonic welding machines.

● Integrated Automatic Unloading Unit

Equipped with an automatic unloading mechanism, the system ensures smooth material flow,

reduces manual intervention, and improves overall production safety and efficiency.

● High Precision Ultrasonic Welding Control

Stable ultrasonic frequency and amplitude control

Consistent weld strength and appearance

Suitable for complex and high-precision plastic components

● PLC + HMI Intelligent Control System

The system adopts a PLC control system with touch screen HMI, allowing operators to easily

adjust parameters, monitor production status, and ensure stable long-term operation.

● Modular & Customizable Structure

Each welding station and automation module can be customized according to product size, material,

and production requirements, making the system ideal for OEM and automated production lines.

This rotary multi-station ultrasonic welding system is suitable for welding a wide range of

thermoplastic materials, including ABS, PP, PE, PS, PC, and nylon.

Common application industries include:

Automotive parts: sensors, filters, plastic housings, interior components

Electronics: connectors, plastic enclosures, switch components

Medical devices: disposable plastic components, sealed housings

Consumer products: packaging parts, daily-use plastic assemblies

High production efficiency for mass manufacturing

Stable and repeatable welding quality

Reduced labor cost through automation

Compact layout suitable for production lines

Easy maintenance and long service life

Compared with traditional manual or single-station ultrasonic welding machines, this system provides

higher output, better consistency, and lower long-term operating costs.

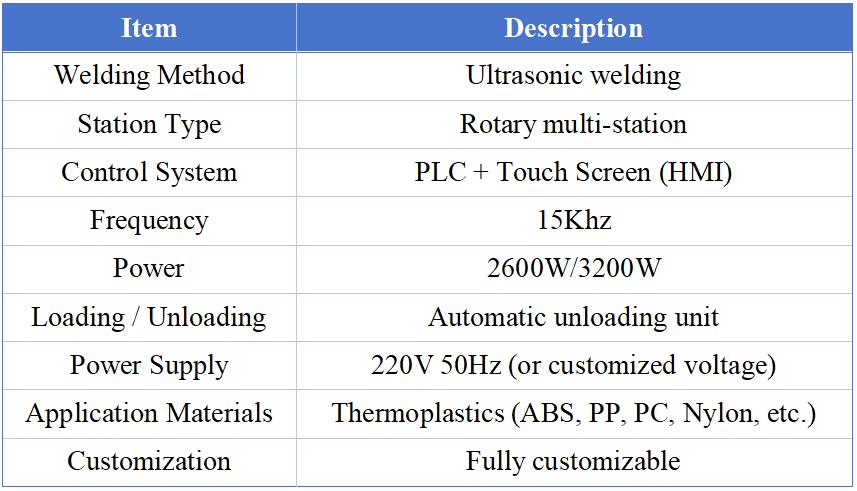

Specifications can be adjusted based on customer product drawings and production requirements.

Over 10 years of experience in ultrasonic welding automation

Strong custom design & manufacturing capability

Strict quality control and factory testing before delivery

Professional technical support and after-sales service

Reliable solutions for global customers

We provide not only machines, but complete ultrasonic welding solutions tailored to your production needs.

Q1: Can this system be customized for our product?

Yes. The rotary table size, number of stations, welding parameters, and unloading method can all be customized

according to your product drawings and output requirements.

Q2: What materials can be welded with this machine?

It is suitable for most thermoplastic materials such as ABS, PP, PC, PE, PS, and nylon.

Q3: Is this system suitable for fully automatic production lines?

Yes. It can be integrated into automated production lines and connected with upstream and downstream equipment.

Q4: Do you provide installation and technical support?

Yes. We provide operation guidance, technical support, and after-sales service to ensure smooth operation.

Get a Customized Quotation Today

If you are looking for a high-efficiency rotary ultrasonic welding system to improve production capacity

and product quality, please contact us.

Get Your Ultrasonic Welding Solution

Tell us your application. Our engineers will reply within 24 hours.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107