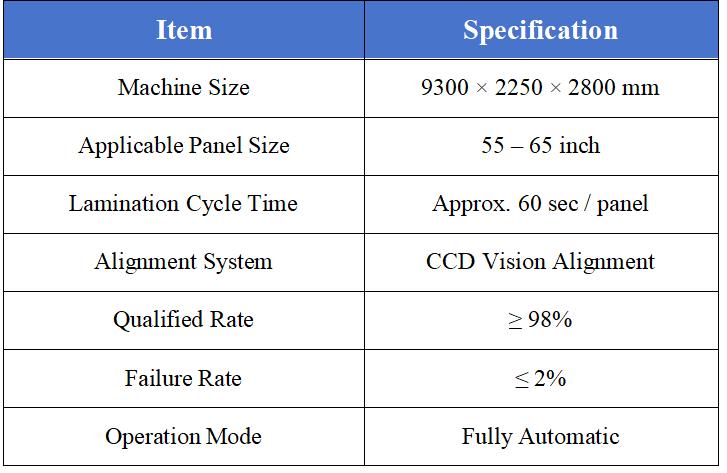

A high-precision automation lamination machine designed to assemble AL sheets (or films) onto 55–65" OLED panels with CCD alignment vision system, high throughput, and production-ready reliability.

A high-precision automation lamination machine designed for laminating AL sheets (or films) onto 55–65 inch OLED panels.

Equipped with CCD vision alignment, this system delivers stable lamination accuracy, high production efficiency,

and consistent quality for display manufacturing lines.

Fully automatic operation

High precision CCD alignment

Stable performance for mass production

Fully automatic process

Automatic feeding, CCD alignment, lamination, and unloading — minimal manual intervention.

High precision CCD vision alignment

Ensures accurate positioning of AL sheet and panel before lamination, improving yield rate.

High production efficiency

Average cycle time around 60 seconds per panel, suitable for mass production lines.

Stable and reliable performance

Qualified rate ≥ 98%, failure rate ≤ 2%, designed for continuous operation.

Reduce labor cost by replacing manual lamination with full automation

Improve lamination accuracy and consistency

Increase production efficiency and reduce cycle time

Stable quality for large-size OLED panels

Easy integration into existing production lines

This system is ideal for manufacturers aiming to improve yield rate and production stability in OLED panel assembly.

OLED TV panel lamination

OLED monitor and display module assembly

Large-size display panel manufacturing

Electronics panel production lines

Customized automation lamination projects

If you have a specific panel size or application, contact us for a customized solution.

Q1. What is an automation lamination machine used for?

A:An automation lamination machine is used to automatically laminate AL sheets or films onto OLED panels with

high precision and consistency. It is widely applied in display panel manufacturing lines to improve productivity

and reduce manual labor.

Q2. What panel sizes can this lamination machine handle?

A:This automation lamination machine is designed for 55–65 inch OLED panels. Custom configurations for

other panel sizes can be evaluated based on project requirements.

Q3. How does CCD vision alignment improve lamination accuracy?

A:The CCD vision system detects reference points on both the panel and AL sheet, ensuring precise alignment

before lamination. This significantly improves positioning accuracy and ensures stable and repeatable lamination quality.

Q4. Is the lamination process fully automatic?

A:Yes. The machine supports fully automatic operation, including material feeding, CCD alignment, lamination,

and unloading, minimizing manual intervention and improving production efficiency.

Q5. Can this machine be integrated into an existing production line?

A:Yes. The automation lamination machine can be customized and integrated into existing OLED or display

manufacturing production lines according to layout and process requirements.

Q6. Do you provide application evaluation or sample testing?

A:Yes. Customers can contact us to discuss application requirements and sample testing to evaluate lamination

results before placing an order.

If you are planning to upgrade your OLED panel production line or replace manual lamination with automation,

our engineering team can help you evaluate the right solution.

Contact Us for Technical Consultation

Fast response • Engineering support • Custom solutions

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107