Automation O-ring Assembly Machine is used for assembly O-ring and plastic core. Automatically loading and unloading, Vision system for analyzing assembly status.

Product Overview

The Custom Automatic O-ring Assembly Machine is a non-standard, fully customized automation solution developed

by Timeast for automotive filter applications.

The system is designed to assemble O-rings onto automotive filter components with high accuracy, consistency, and

production stability.It has been designed, manufactured, and delivered for a top-tier automotive components manufacturer

in North America, meeting automotive-grade quality and reliability requirements.

This solution is suitable for high-volume automotive production environments where sealing performance, process stability, and long-term operation are critical.

Application: Automotive filter O-ring assembly

Production mode: High-volume, continuous manufacturing

Key requirements:

Accurate and repeatable O-ring positioning

Stable long-term operation

Reduction of manual labor and defect rate

Compatibility with existing production lines

Timeast provided a customized automation solution based on the customer's filter structure,

O-ring specifications, and target cycle time.

1. Automotive-Grade Design

Specifically designed for automotive filter sealing applications

Ensures consistent O-ring placement and reliable sealing performance

2. Non-Standard Custom Automation

Machine structure, feeding system, and assembly process are fully customized

Adapted to unique product geometry and production workflow

3. High Precision & Repeatability

Stable mechanical structure ensures accurate O-ring installation

Reduces risks of missing, misaligned, or damaged O-rings

4. Inline Inspection (Optional)

Supports vision inspection to verify O-ring presence and position

Automatically separates NG parts to ensure outgoing quality

5.Production-Line Integration

Can be used as a standalone station or integrated inline

Designed for multi-shift, continuous automotive production

Automatic O-ring feeding

Automotive filter component positioning

Precision O-ring assembly

Inline inspection (optional)

OK / NG separation

Finished product output

The entire process is automated to ensure consistent quality and production stability.

Watch the demonstration to see how this automated O-ring assembly solution improves reliability and

efficiency in automotive filter production.

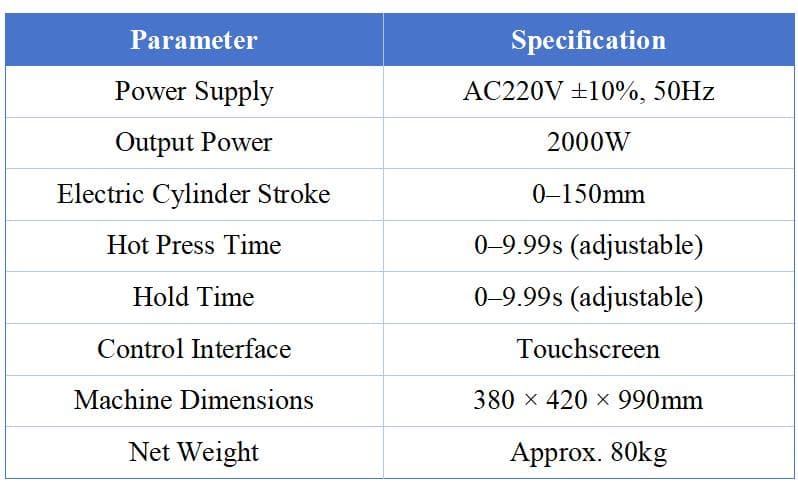

Final specifications are customized according to customer product design and automotive manufacturing standards.

Oil filter O-ring assembly

Air filter O-ring assembly

Fuel filter O-ring assembly

Other automotive sealing components

This automation solution has been successfully delivered and validated in a high-volume automotive production

environment for a leading international automotive components manufacturer.

It reflects Timeast’s capability to deliver production-ready, automotive-grade automation solutions for demanding

customers.

Q1: Is this a standard machine?

A: No. This is a fully customized non-standard automation solution, developed based on specific

product and process requirements.

Q2: Can the machine support future product changes?

A: Yes. The system can be designed with flexibility to support product upgrades or multiple filter models.

Q3: Is the solution suitable for continuous production?

A: Yes. It is designed for long-term, multi-shift automotive production with stable operation.

Q4: Do you have experience with overseas automotive customers?

A: Yes. Timeast has experience delivering custom automation solutions for international automotive manufacturers.

Contact Timeast to receive:

Technical feasibility analysis

Customized automation proposal

Professional quotation

Send Inquiry | Discuss Your Application | Request a Custom Solution

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107