Introduction

In advanced manufacturing, welding technology plays a pivotal role in joining components

with strength, precision, and speed. Among welding methods, ultrasonic welding stands out

for its ability to deliver clean, fast, and reliable bonds without adhesives, solvents, or excessive heat.

While high-frequency ultrasonic welders (20–40kHz) are common for small parts, low-frequency

high-power systems like the 15kHz 4200W ultrasonic welding equipment excel in demanding industrial

applications requiring deep energy penetration and robust joints.

In this article, we explore what makes 15kHz ultrasonic welding equipment special — its advantages,

industry applications, and why it could be the best choice for large-part manufacturing.

What Is 15kHz Ultrasonic Welding and Why It Matters

Ultrasonic welding creates a solid bond between thermoplastic parts or hybrid materials by

applying mechanical vibrations at ultrasonic frequencies directly to the contact area.

Instead of melting the entire piece, localized heat generated by friction causes surfaces to

soften and fuse into a strong molecular joint.

The 15kHz frequency band is especially valuable for industrial tasks because:

Low frequency + high amplitude delivers deeper energy penetration, ideal for thick or high-mass parts.

Robust power output (4200W) ensures welding strength under heavy loads and high-cycle conditions.

This combination increases reliability and consistency in demanding manufacturing environments.

Learn more about an example of industrial 15kHz ultrasonic welding equipment here:

https://www.sztimeast.com/product/15kHz-4200W-Ultrasonic-Welding-Equipment.html

5 Key Advantages of 15kHz Low-Frequency Welding Systems

1. Deep Penetration for Thick-Wall Parts

Unlike higher-frequency ultrasonic machines that target thin or delicate plastics,

15kHz systems push energy deeper into the joint area, making them suitable for:

Thick plastic housings

Automotive structural components

Large assemblies with complex geometries

This strength is essential in industries where joint strength and durability are non-negotiable.

2. High Power for High-Strength Bonds

With 4200W of power, these machines generate sufficient vibrational force to handle large surface areas

and demanding industrial workloads. High power levels help maintain weld quality and repeatability

even on heavy-duty assemblies.

3. Faster Cycle Times = More Productivity

Ultrasonic welding’s inherent efficiency shines in high-volume production. Typically, weld cycles

are completed in seconds, enabling significant throughput improvements compared with traditional

thermal or adhesive methods.

4. Cleaner & Eco-Friendly Process

Ultrasonic welding doesn’t use solvents or adhesives, minimizing environmental impact and eliminating

post-weld cleanup. This makes the process especially attractive in medical device and packaging sectors

where cleanliness is critical.

5. Better Integration with Modern Automated Lines

Modern 15kHz welding systems can be combined with PLC controls, vision inspection, and data logging,

facilitating integration into Industry 4.0 automation and smart manufacturing workflow

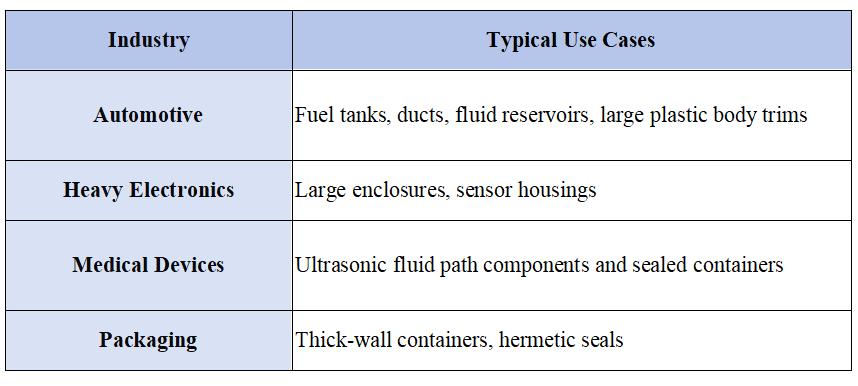

Where 15kHz 4200W Ultrasonic Systems Shine — Real Industrial Applications

In automotive manufacturing, for example, these systems have been deployed for thick-wall plastic assemblies

with stable weld strength and low cosmetic defects — all while keeping cycle times production-friendly.

How It Works: The Engineering Behind Powerful Ultrasonic Welding

A 15kHz ultrasonic welding system typically includes:

Ultrasonic generator — Provides the high-frequency electrical signal

Transducer (converter) — Converts electrical energy into mechanical vibration

Booster & horn (sonotrode) — Amplifies and applies vibrational energy to the parts

The sonotrode, often made from titanium or special alloys, directs ultrasonic energy precisely

where it’s needed, ensuring efficient heat generation and molecular fusion without material degradation.

Choosing the Right System — What Buyers Should Know

When evaluating 15kHz ultrasonic welding equipment, consider:

Power capacity (e.g., 4200W vs lower power models)

Amplitude control and adjustability

Compatibility with part materials and thickness

Automation interface and data logging capability

Selecting a machine that matches your parts’ material and production rhythm is crucial for

long-term performance and ROI.

Conclusion

15kHz 4200W ultrasonic welding equipment represents a powerful, efficient, and environmentally friendly

joining technology for industrial manufacturing. Thanks to deeper energy penetration, high power output,

rapid cycle times, and automation readiness, this class of ultrasonic systems is ideal for automotive, heavy plastics,

and complex assemblies where traditional welding falls short.

Whether your production demands strength, speed, or cleanliness, a 15kHz ultrasonic welding system

could unlock significant gains in productivity and product quality.

Ready to explore a customized solution for your application?

Contact us to discuss your parts and get a tailored recommendation.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107