The 15kHz 4200W ultrasonic welding machine is designed for large-sized and thick-wall plastic welding applications.

With low frequency and high amplitude, it provides deep ultrasonic energy penetration, ensuring strong and reliable welds.

This industrial ultrasonic welding system is widely used in automotive, industrial containers, home appliances, and customized plastic assemblies.

A. Low Frequency (15kHz) – High Energy Output

Ideal for welding large, thick, or complex plastic components

4200W High-Power Generator

Ensures stable welding performance and deeper fusion

B. Excellent Weld Strength & Consistency

Reduced defect rate and improved production yield

C. Industrial-Grade Stability

Designed for long-time continuous operation

D. Flexible Integration

Compatible with manual stations, semi-automatic or automated production lines

This 15kHz ultrasonic welding machine is commonly used for:

Automotive air ducts & fluid containers

Large plastic housings and structural parts

Thick-wall plastic tanks and covers

Industrial plastic components requiring high weld strength

Custom oversized plastic welding projects

If your application involves large size, thick material, or high structural strength,

15kHz ultrasonic welding is the ideal solution.

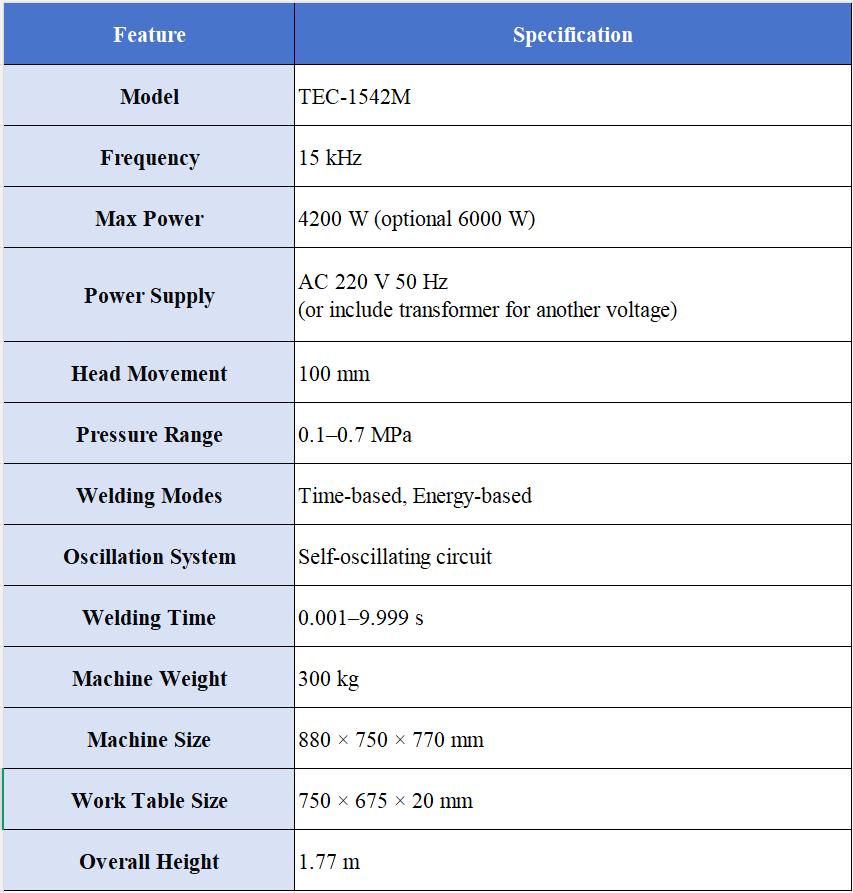

Technical specifications can be customized based on your application.

Compared with 20kHz or higher frequencies, 15kHz ultrasonic welding offers:

Higher amplitude for thick-wall and large parts

Better energy transfer for high-strength joints

Improved reliability for demanding industrial applications

Our engineers help customers select the right frequency and power configuration

based on real welding requirements.

Stronger weld joints with reduced failure risk

Improved production efficiency

Lower scrap and rework rate

Professional technical support from application to commissioning

Q: What is the difference between 15kHz and 20kHz ultrasonic welding?

A: 15kHz provides higher amplitude and deeper energy penetration, making it more

suitable for large or thick plastic parts.

Q: Can the welding horn be customized?

A: Yes. We provide customized horns and fixtures based on your product design.

Q: Is this machine suitable for automation lines?

A: Absolutely. The system supports integration with automated production lines.

Q: What is the delivery time?

A: Standard models ship quickly; customized solutions depend on specifications.

Get Your Ultrasonic Welding Solution

Tell us your application. Our engineers will reply within 24 hours.

Related Article

Unlocking Power:How 15kHz 4200W Ultrasonic Welding Equipment TransformsIndustrial Assembly

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107