Double Heads Ultrasonic Welding Machine is a dual-head high-power ultrasonic welding system designed for simultaneous dual spot welding, suitable for a wide range of thermoplastics welding applications, enabling higher efficiency, better weld consistency, and reduced production costs.

A high-performance double heads ultrasonic welding machine designed for simultaneous or

independent welding operations.

Equipped with advanced digital control and intelligent amplitude adjustment, this system delivers stable energy output, wide material compatibility, and robust weld quality for automotive, electronics,

consumer goods, and industrial manufacturing.

Key benefits:

Dual heads enable faster throughput and higher production efficiency

Stepless amplitude control for adaptability to different product requirements

Intelligent protection and fault alarm system for safer and reliable operation

Contact Us for Application Support

This machine is ideal for thermoplastic welding in industries such as:

Automotive components welding

Electronics and connectors assembly

Consumer products (toys, appliances)

Packaging and sealing applications

Medical device plastic welding

Multi-point large parts plastic assembly

Ultrasonic welding creates a strong bond without adhesives, screws, or solvents, and is

widely used because it is clean, quick, and energy-efficient.

Dual Head Efficiency: Weld two spots simultaneously or independently, doubling productivity.

High Performance Output: IGBT power modules and smart control deliver strong and stable ultrasonic energy.

Stepless Amplitude Adjustment: Adapts to various product thickness and material needs.

Multiple Welding Modes: Flexible and accurate welding, suited for different processes.

Intelligent Protection: Includes over-current, frequency deviation, and output safety alarms for safe operation.

User-Friendly Touchscreen Interface: Easy digital parameter setting and operation.

Dual ultrasonic heads for large size or high-volume welding jobs.

Dual head modes: work simultaneously or separately.

Automatic frequency tracking to prevent frequency deviation.

High-quality pneumatic components and stable mechanical structure.

Intelligent closed-loop amplitude control for consistent output.

Multiple welding modes for broader applicability.

Digital touch screen for intuitive and precise control.

Intelligent protection and fault alarms for safe operation.

Watch the Double Heads Ultrasonic Welding Machine in action — simultaneous dual-spot welding and

weld quality assessment.

Q1. What is a double heads ultrasonic welding machine?

A double heads ultrasonic welding machine uses two ultrasonic welding horns that can operate simultaneously

or independently to improve throughput and welding consistency.

Q2. What materials can it weld?

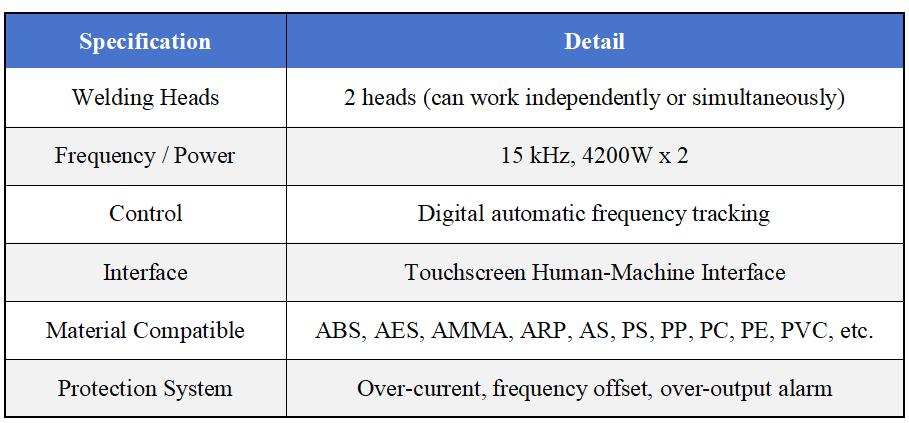

It is suitable for a wide range of thermoplastics including ABS, PP, PC, PE, PS, PVC and more.

Q3. Why choose double heads instead of single head?

Dual heads can weld multiple points at once, doubling efficiency and reducing cycle time for high‐volume production.

Q4. How is ultrasonic welding different from traditional welding?

Ultrasonic welding uses high-frequency sound waves to generate heat at the material interface, joining parts without

adhesives or external heat sources.

Q5. Can this machine be customized?

Yes — parameters, fixtures and control options can be customized for different product applications and production

line integration.

Whether you need to weld large plastic parts, automate high-volume production, or evaluate material compatibility,

our engineers are ready to assist.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107