When there are vulnerabilities or pores inside a closed system, the gas within the system will flow from high-pressure areas to low-pressure areas, resulting in pressure changes. Air tightness detection equipment utilizes this characteristic to determine whether a system has vulnerabilities or sealing issues by monitoring the pressure differential and gas flow inside and outside the closed system. Air tightness detection equipment is an important testing device based on the principles of gas flow and pressure changes. It determines whether a product has leakage issues through precise processes of inflation, pressure stabilization, and balancing, thereby ensuring product quality and reliability.

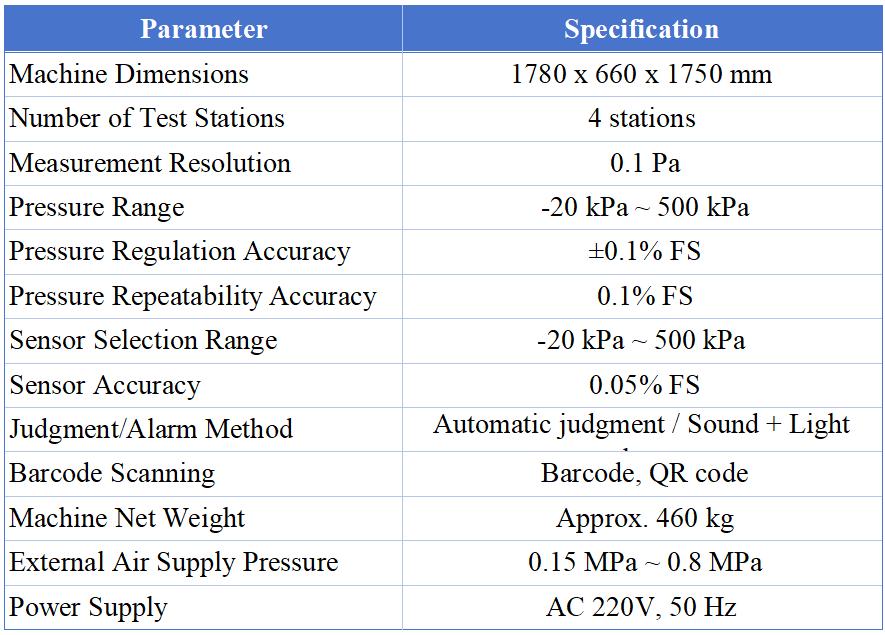

Precision Air Leak Testing Machine (4 Stations)

High-accuracy pressure decay leak testing for sealed parts. Designed for stable, repeatable results in

mass production with automated judgement and traceability options.

4 stations to boost throughput for production lines

0.1 Pa resolution; sensor accuracy up to 0.05% FS

Wide pressure range: -20 kPa to 500 kPa

Automatic PASS/FAIL judgement with sound & light alarm

Barcode/QR code scanning for traceability (optional data export)

Ideal for leak testing of sealed housings, valves, reservoirs, connectors, medical consumables, and consumer

electronics enclosures.

Inflation → Stabilization → Detection → Automatic Judgement. Parameters (test pressure, stabilization time,

detection time) are configurable based on part volume and target leak rate.

Custom fixtures, data logging/export, Ethernet/serial communication, MES/PLC integration, multi-language UI.

12-month warranty (excluding consumables) + lifetime technical support. Remote support via video/phone/email.

Overseas on-site service available.

Send your part drawing, cavity volume (if known), test pressure requirement, and target leak rate.

Related Article:

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107