Custom ultrasonic welding automation line developed for a leading U.S. automotive parts manufacturer.

Designed for automotive filter end caps and nonwoven sealing materials with automatic loading,

welding, inspection, and unloading. Customer-specific automation solutions.

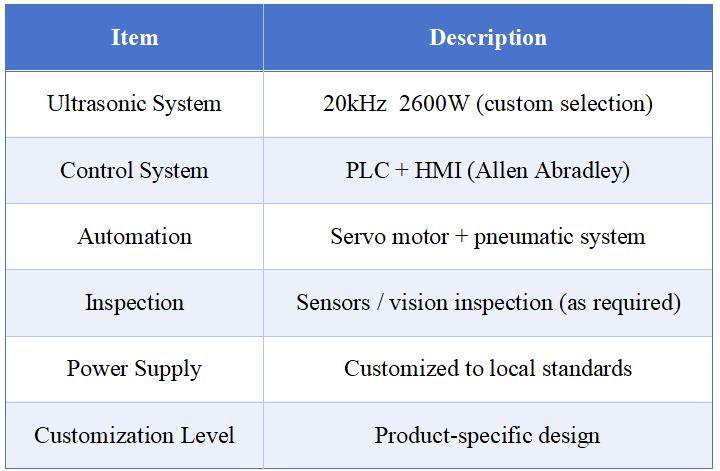

This ultrasonic welding automation line is a customer-specific production system developed for

a well-established U.S. automotive parts manufacturer serving the European and North American

automotive markets.

The system is designed exclusively for the automatic welding of automotive filter end caps and

nonwoven sealing cotton materials, integrating automatic loading, ultrasonic welding, inspection,

and unloading into one stable and efficient production line.

This is not a standard or off-the-shelf machine.

Each system is engineered based on the customer’s actual product design, materials, and production requirements.

This video demonstrates the full operational process of the custom ultrasonic welding automation line for

automotive filter end caps, including automatic material loading, precision ultrasonic welding, in-line inspection,

and automatic unloading. It showcases machine stability, welding precision, and efficient automation flow.

Application Scope

This automation solution is developed for the automotive filtration industry, specifically for:

Automotive filter end caps

Nonwoven sealing cotton materials

The ultrasonic welding process ensures strong bonding, clean joints, and high repeatability,

meeting the stability and durability requirements of automotive components.

Automatic material loading

Precision ultrasonic welding

In-line quality inspection

Automatic unloading of finished parts

The entire process is controlled by a PLC system, ensuring consistent cycle time, stable welding quality,

and reduced manual intervention.

Designed specifically for automotive filter components

Optimized ultrasonic welding for plastic and nonwoven materials

Stable operation suitable for long-term mass production

Integrated inspection to ensure welding consistency

Reduced labor cost and human error

Engineered for automotive production reliability standards

Custom-designed fixtures and tooling for filter end caps

Welding parameters optimized for nonwoven sealing materials

Automation sequence tailored to customer production flow

Safety enclosure designed for factory operation standards

Modular design for maintenance and future upgrades

This system represents a custom automation project for a well-known U.S. automotive parts brand,

demonstrating our ability to deliver reliable, high-precision ultrasonic welding automation solutions

for demanding automotive applications.

This machine is a customer-specific automation system.

It cannot be directly applied to other products.

For new projects, we design and manufacture custom ultrasonic welding automation solutions

based on each customer’s specific product and process requirements.

Extensive experience in automotive ultrasonic welding automation

Strong in-house engineering and mechanical design capability

Proven projects for European and North American automotive customers

One-stop service: design, manufacturing, installation, and training

Long-term technical support and fast response

Looking for a custom ultrasonic welding automation line for automotive filter components or similar applications?

To receive a technical evaluation, please provide:

Product drawings or samples

Material information

Required production capacity

Quality or inspection requirements

Contact us today to discuss your project.

Our engineering team will provide a tailored automation solution.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107