When assembling plastic parts, choosing the right joining method has a direct impact on product quality,

appearance, strength, and production cost.

Among the most common plastic assembly technologies are:

Ultrasonic welding

Heat staking

Vibration welding

Each process has its own advantages and limitations.

In this article, we compare ultrasonic welding vs heat staking vs vibration welding, helping you select the

most suitable solution for your plastic assembly application.

1)What Is Ultrasonic Welding?

Ultrasonic welding uses high-frequency mechanical vibration to generate frictional

heat at the joint interface, melting and bonding thermoplastic materials without external heat sources.

Key Characteristics of Ultrasonic Welding

Very fast cycle time (typically < 1 second)

Strong, consistent weld joints

Clean process with no consumables

Suitable for automation

Excellent for precision and cosmetic plastic parts

Ultrasonic welding is widely used in automotive, medical, electronics, and consumer products.

2)What Is Heat Staking?

Heat staking is a thermal process that uses a heated tip to soften and deform plastic studs,

mechanically fastening two parts together.

Key Characteristics of Heat Staking

Simple and low-cost equipment

Suitable for plastic-to-plastic or plastic-to-metal assembly

Slower cycle time compared to ultrasonic welding

Mechanical joint rather than molecular bond

Limited joint strength

Heat staking is often used where structural strength and sealing are not critical.

3)What Is Vibration Welding?

Vibration welding joins plastic parts by applying low-frequency vibration under pressure,

generating frictional heat across a large joint surface.

Key Characteristics of Vibration Welding

Suitable for large, irregular-shaped parts

High joint strength

Visible weld marks and particle generation

Larger equipment footprint

Not ideal for cosmetic surfaces

Vibration welding is commonly used for automotive fluid reservoirs, large containers,

and structural components.

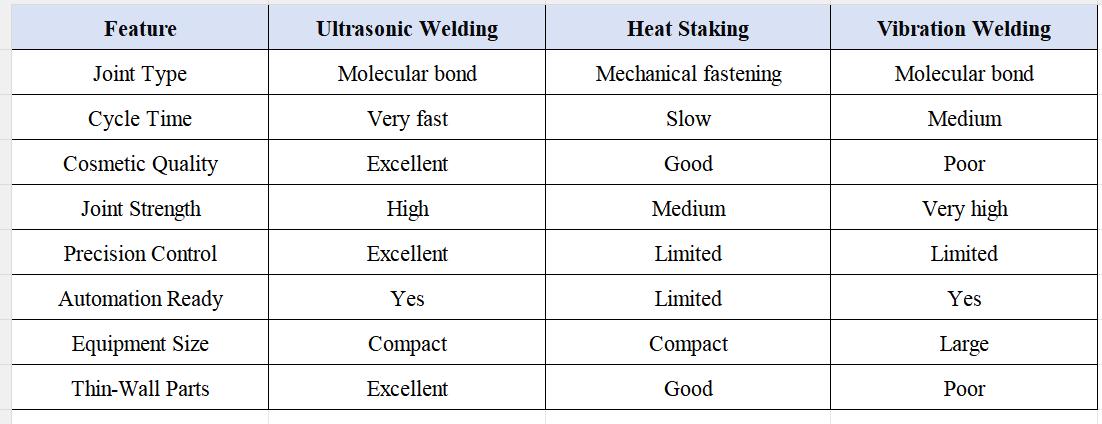

4)Key Differences: Plastic Assembly Method Comparison

5)When Should You Choose Ultrasonic Welding?

Ultrasonic welding is the best choice when:

High production speed is required

Parts have thin walls or cosmetic surfaces

Tight dimensional tolerances must be maintained

Automation and repeatability are important

Clean, particle-free assembly is required

Ultrasonic welding offers the best balance between speed, strength, and appearance for most

precision plastic assemblies.

6)When Is Heat Staking a Better Option?

Heat staking may be suitable if:

Assembly involves plastic-to-metal inserts

Structural strength is not critical

Production volume is low

Budget constraints are strict

However, it is not ideal for sealed or load-bearing joints.

7)When Should You Use Vibration Welding?

Vibration welding is typically chosen when:

Parts are large or complex in shape

High structural strength is required

Cosmetic appearance is not important

Particles and weld flash are acceptable

It is often used in heavy-duty automotive or industrial applications.

Conclusion: Choosing the Right Plastic Welding Method

There is no universal plastic joining method that fits all applications.

Ultrasonic welding → Precision, speed, cosmetic quality

Heat staking → Simple fastening, low cost

Vibration welding → Large parts, high strength

Understanding your material, part design, quality requirements, and production volume is

essential before selecting the right process.

If you are considering ultrasonic welding for precision plastic parts and want to know whether

it fits your application:

Send us your part drawings or samples,Get a free welding evaluation.

Free technical evaluation | Customized solutions | Fast response within 24 hours

Learn more about Ultrasonic Welding Solutions

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107