Choosing the right ultrasonic welding system is critical for achieving consistent quality,

especially when welding high-precision or thin-wall plastic parts.

Many manufacturers struggle to decide between servo driven ultrasonic welding and

traditional pneumatic ultrasonic welding.Although both technologies are widely used,

they serve very different application requirements.

In this article, we compare servo driven vs pneumatic ultrasonic welders, explain their

working principles, and help you determine which solution is best for your plastic

welding application.

What Is Pneumatic Ultrasonic Welding?

A pneumatic ultrasonic welder uses compressed air to drive the welding head downward.

The welding force and movement are controlled by air pressure and mechanical stops.

Key Characteristics of Pneumatic Ultrasonic Welding

Cost-effective solution

Simple structure and easy maintenance

Suitable for thick or structural plastic parts

Limited control over exact welding depth and force

Sensitive to air pressure fluctuations

Pneumatic ultrasonic welding is commonly used for general-purpose plastic welding, where

cosmetic appearance and micron-level accuracy are not critical.

What Is Servo Driven Ultrasonic Welding?

A servo driven ultrasonic welder uses an electrical servo motor instead of compressed air to control

the welding movement.This allows closed-loop control of: Position,Speed,Force,Welding depth

As a result, servo ultrasonic welding delivers higher repeatability and precision, even when

part tolerances vary.

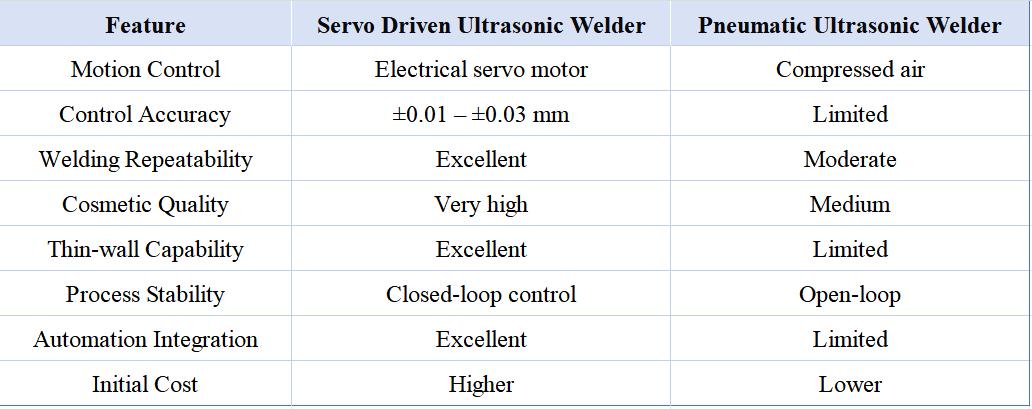

Key Differences: Servo Driven vs Pneumatic Ultrasonic Welding

When Should You Choose a Servo Driven Ultrasonic Welder?

A servo driven ultrasonic welding machine is the better choice if your application involves:

1. Thin-Wall Plastic Parts

Servo control minimizes deformation, flash, and whitening, which is critical for thin or cosmetic parts.

2. High Precision & Tight Tolerances

Closed-loop position control ensures consistent welding depth across parts.

3. Cosmetic or Visible Components

Improves surface appearance and reduces post-processing.

4. Medical & Electronics Applications

Where repeatability, traceability, and process control are required.

5. Automated Production Lines

Servo ultrasonic welders integrate easily with PLC, MES, and robotic systems.

When Is Pneumatic Ultrasonic Welding Still a Good Option?

Pneumatic ultrasonic welding may still be suitable if:

Parts are thick and structural

Cosmetic appearance is not critical

Budget is the main concern

Process variation is acceptable

In these cases, pneumatic systems provide a cost-effective and reliable solution.

Why Servo Driven Ultrasonic Welding Improves Production Consistency

Servo driven systems maintain constant welding parameters, regardless of:

Material variation

Part dimensional changes

Environmental conditions

This leads to:

Lower scrap rate

Reduced rework

Higher yield

Better long-term quality control

For manufacturers focused on high-value plastic products, servo ultrasonic welding delivers measurable ROI.

Conclusion: Which Ultrasonic Welding Technology Is Right for You?

There is no single “best” ultrasonic welding technology — the right choice depends on your product design,

quality requirements, and production goals.

For general plastic welding → Pneumatic ultrasonic welding

For precision, thin-wall, cosmetic or automated applications → Servo driven ultrasonic welding

Need Help Selecting the Right Ultrasonic Welding Solution?

If you are working with high-precision plastic parts and are unsure whether servo driven ultrasonic welding

is suitable for your application:

Send us your part drawings or samples

Get a free welding evaluation from our engineers

Learn more about our Electrical Servo Driven Ultrasonic Welder

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107