Ultrasonic welding is widely used to seal plastic components, but many manufacturers still encounter

leak test failures even when the weld looks perfect.

In this FAQ-style guide, we answer the most common leak testing problems after ultrasonic welding,

explain why they occur, and show how proper air leak testing helps identify and solve them.

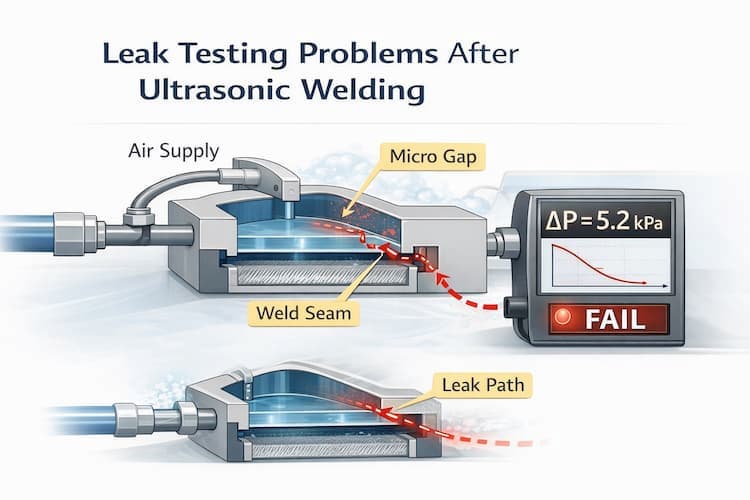

FAQ 1: Why Do Welded Parts Fail Leak Tests Even When the Weld Looks Good?

Short answer:

Because visual inspection cannot detect micro-leaks.

Common causes include:

Incomplete energy transfer at the weld interface

Material shrinkage after cooling

Internal stress causing micro-gaps along the weld line

Even tiny defects invisible to the eye can cause pressure loss during leak testing.

Solution:

Use air leak testing (pressure decay or differential pressure) to objectively verify sealing integrity.

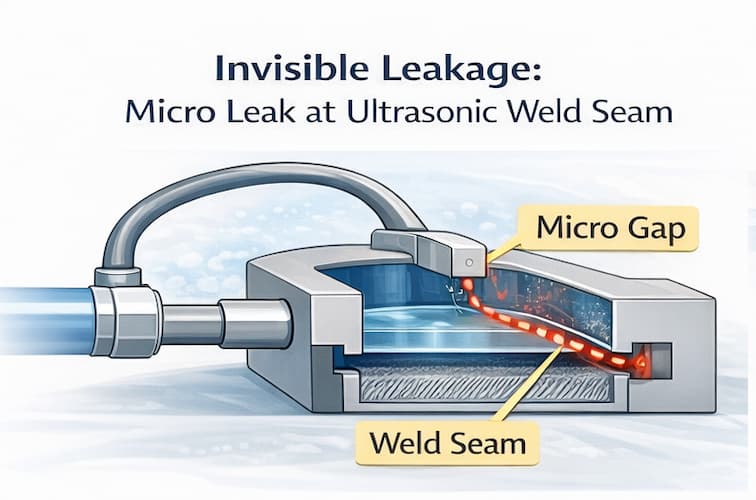

FAQ 2: What Is the Most Common Leak Location After Ultrasonic Welding?

Most leaks occur at:

The weld seam

Corners and sharp transitions

Areas with uneven wall thickness

These areas are sensitive to welding parameter variation and part tolerance.

Tip:

Leak test data can help identify recurring weak points and guide weld parameter optimization.

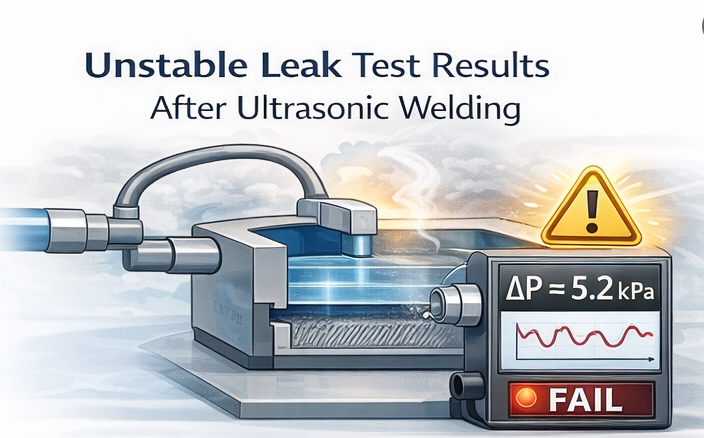

FAQ 3: Why Are Leak Test Results Unstable or Inconsistent?

Unstable results are often caused by:

Insufficient pressure stabilization time

Temperature variation after welding

Fixture leakage instead of part leakage

Part deformation during clamping

Solution:

Allow proper cooling before testing

Optimize stabilization and detection time

Use well-sealed, customized fixtures

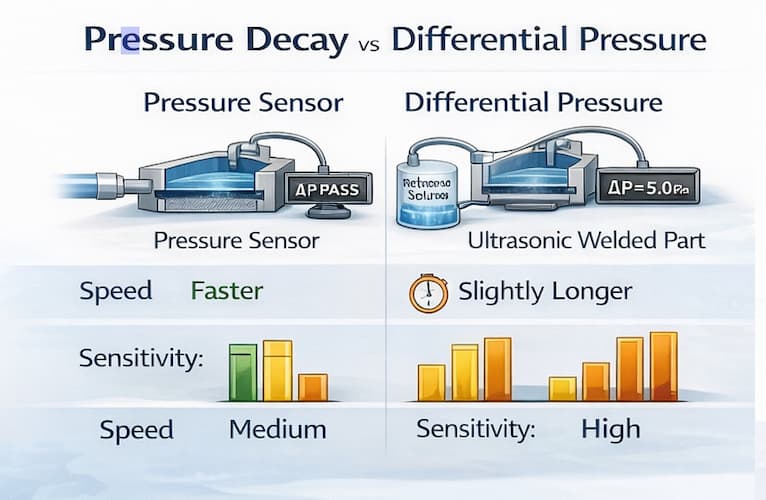

FAQ 4: Pressure Decay or Differential Pressure—Which Is Better After Welding?

It depends on your application:

1 Pressure Decay Testing

Faster and simpler

Suitable for most welded plastic parts

2 Differential Pressure Testing

Higher sensitivity

Ideal for micro-leak detection and small volumes

Many manufacturers start with pressure decay and upgrade to differential testing when

higher precision is required.

FAQ 5: Can Leak Testing Help Improve the Ultrasonic Welding Process?

Yes—this is often overlooked.

Leak testing is not only a pass/fail inspection, but also a process optimization tool:

Identifies unstable welding parameters

Confirms consistency across production batches

Reduces scrap and rework

When leak testing is integrated directly after ultrasonic welding, quality issues are detected early.

FAQ 6: How Can Leak Testing Be Integrated Into a Production Line?

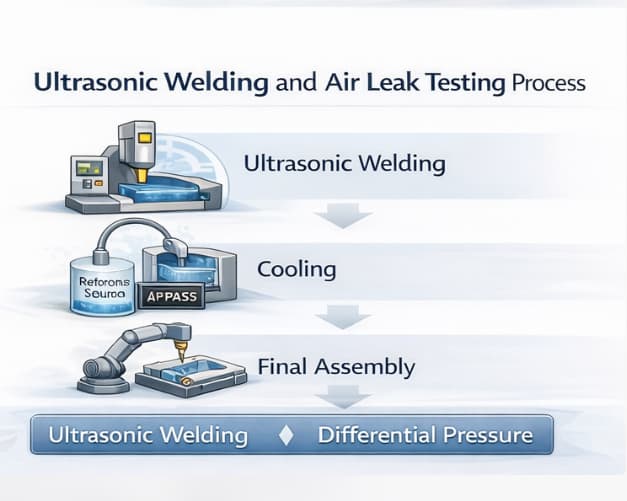

A typical workflow is:

Ultrasonic Welding → Cooling → Air Leak Testing → Final Assembly

Modern air leak testing machines support:

Multi-station testing

Automatic judgement

Data logging and traceability

This makes them suitable for inline inspection in mass production.

Conclusion

Leak test failures after ultrasonic welding are common—but they are also preventable.

By understanding typical leak problems and applying the right air leak testing method, manufacturers

can significantly improve weld quality, reduce defects, and ensure reliable sealing performance.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107