The electrical servo driven ultrasonic welder is designed for high-precision plastic welding applications where accurate control of force, position, and welding depth is critical.

Unlike traditional pneumatic ultrasonic welders, the servo-driven system uses closed-loop motion control, ensuring repeatable weld quality, improved cosmetic appearance, and reduced part variation impact.

This ultrasonic welding solution is widely used in medical devices, consumer electronics, automotive interior parts, and other precision plastic assemblies.

Electrical servo driven Z-axis with closed-loop position and force control

High repeatability for precision plastic welding

Reduced welding flash and whitening on cosmetic surfaces

Programmable welding profiles for complex applications

Supports time, energy, and depth welding modes

Data recording and MES interface available

Suitable for automation and smart manufacturing lines

This servo ultrasonic welding machine is ideal for applications requiring tight tolerances

and high cosmetic standards, such as:

Thin-wall plastic housings

Medical plastic components

Consumer electronics enclosures

Automotive interior decorative parts

Multi-layer or sealed plastic assemblies

Precision connectors and plastic fittings

Servo Advantages

Compared with pneumatic ultrasonic welding systems, servo driven ultrasonic welders provide:

Precise control of welding depth and pressure

Consistent results despite part tolerance variations

Better surface appearance and reduced material stress

Improved process repeatability and traceability

This makes servo ultrasonic welding especially suitable for high-value, precision plastic products.

Pneumatic Better If:

Structural thick-wall parts

Budget priority projects

No cosmetic requirement

This video presents the real working process of the electrical servo driven ultrasonic welder,

including precise force and depth control, servo motion performance, and welding repeatability demonstrations.

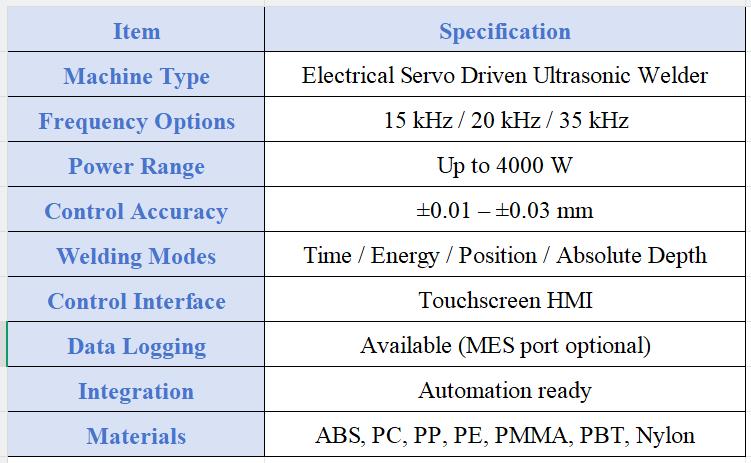

Specifications can be customized based on application requirements.

The servo ultrasonic welder supports automation integration, including:

Robotic loading systems

Automated production lines

PLC and MES communication

Production data tracking and quality control

It is suitable for Industry 4.0 manufacturing environments.

TIMEAST is a professional manufacturer of ultrasonic welding equipment, offering:

Customized welding solutions

Application testing and sample evaluation

Technical support from design to commissioning

Reliable after-sales service

Q1: What is the advantage of servo driven ultrasonic welding?

A: Servo systems provide precise control of force and position, improving consistency and cosmetic quality.

Q2: Is this machine suitable for thin-wall plastic parts?

A: Yes. Servo control minimizes deformation and flash, making it ideal for thin-wall applications.

Q3: Can the welder be integrated into an automated line?

A: Yes. It supports automation, PLC control, and MES data interface.

Q4: Can you provide welding tests before purchase?

A: Yes. We offer free welding evaluation based on customer samples or drawings.

Get Your Ultrasonic Welding Solution

Free technical evaluation | Customized solutions | Fast response within 24 hours

Typical Solutions

Related Articles

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107