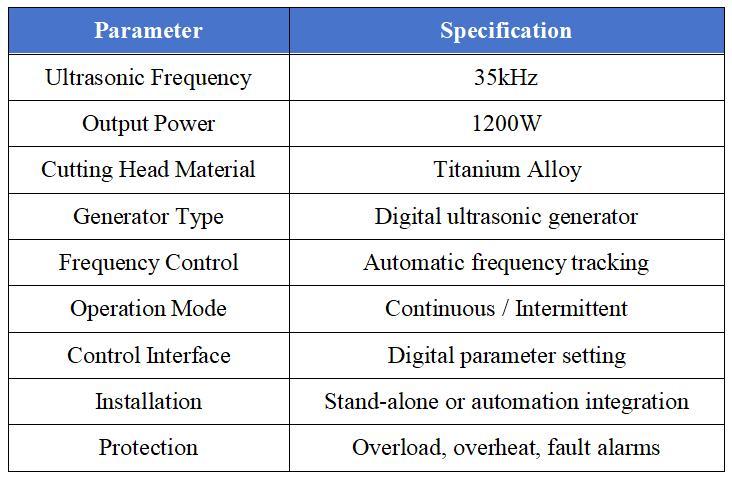

Industrial ultrasonic cutting demo using a 35kHz 1200W ultrasonic cutting system with titanium alloy cutting head.

The system delivers clean edges, minimal heat affected zone, and stable cutting performance for industrial applications.

The 35kHz 1200W Ultrasonic Cutting System with Titanium Alloy Cutting Head is designed for

manufacturers who need clean edges, minimal heat impact, and stable cutting performance.

By using high-frequency ultrasonic vibration instead of mechanical force, this system delivers smooth, burr-free

cuts while protecting material integrity.

Ideal for plastics, composites, textiles, rubber, films, and other delicate materials.

Clean cutting edges — no burrs, no fraying

Minimal heat affected zone (HAZ)

Reduced material deformation

Low tool wear & maintenance

Stable, repeatable industrial performance

Send Your Part for Cutting Evaluation

35kHz High-Frequency Ultrasonic Cutting

Precision vibration for controlled, low-force cutting

1200W Industrial Power Output

Stable performance for continuous operation

Titanium Alloy Cutting Head

Durable, corrosion-resistant, long service life

Automatic Frequency Tracking

Maintains optimal cutting conditions under varying loads

Compact & Automation-Ready Design

Easy integration into production lines

Plastic components & profiles

Composite and carbon-fiber materials

Textiles and non-woven fabrics

Rubber seals and gaskets

Films, foils, and laminated materials

Precision parts requiring low-heat processing

See real cutting performance using a 35kHz ultrasonic cutting system

Clean cuts, minimal heat, and stable operation demonstrated in real industrial conditions.

High-frequency ultrasonic vibration (35kHz) is transmitted to the titanium alloy cutting head.

This vibration reduces friction and cutting resistance, allowing materials to be separated cleanly

with minimal heat and force.

Cutting performance depends on material type, thickness, and application requirements.

We support manufacturers with sample cutting tests and technical evaluation before purchase.

Sample cutting test using your actual material

Feasibility and parameter evaluation

Technical feedback from ultrasonic cutting engineers

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107