Ultrasonic welding is one of the fastest, cleanest, and most repeatable methods to join thermoplastic parts. It uses high-frequency vibration and pressure to generate heat at the joint interface, melting plastic locally and forming a strong bond—often in under a second. No adhesives, no solvents, and no long cure times.

But if you’re specifying an ultrasonic welding system (or troubleshooting a process), one question comes up quickly:

Should you use 15kHz, 20kHz, or 35kHz ultrasonic welding?

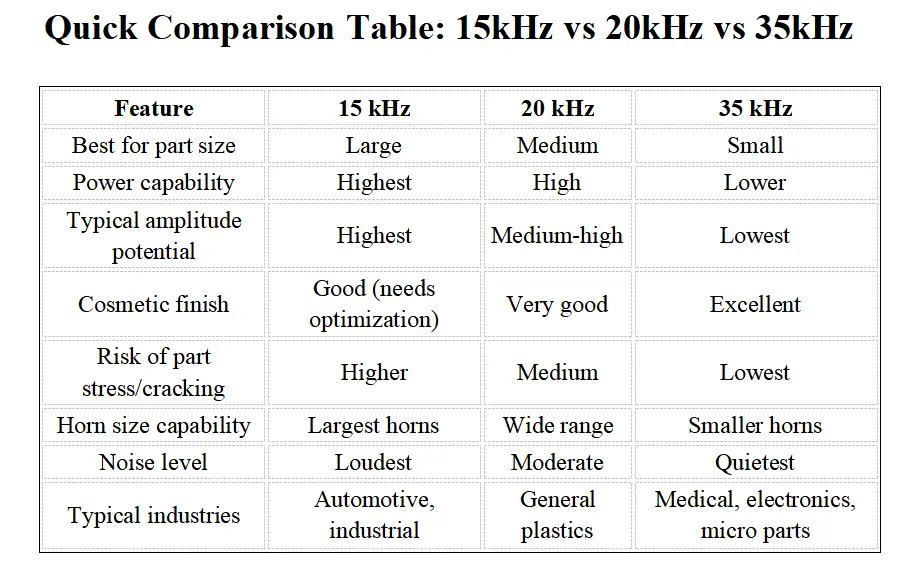

The frequency you choose affects nearly everything—power capability, amplitude, tooling size, cosmetic appearance, part stress, and the kind of parts you can weld reliably. In this complete guide, we’ll break down each frequency, compare them head-to-head, and share practical selection rules used in production environments.

Ultrasonic welding frequency refers to how many times per second the horn (sonotrode) vibrates:

15 kHz = 15,000 vibrations per second

20 kHz = 20,000 vibrations per second

35 kHz = 35,000 vibrations per second

The horn transfers these vibrations into the parts under clamping force. The friction and molecular excitation at the joint creates heat, melting the plastic and fusing it as it cools.

Frequency impacts:Power output,Amplitude range , Horn size limits, Part stress, Cosmetic quality,Noise level, Process repeatability

A useful way to think of it:

15kHz = heavy hitter (maximum power)

20kHz = workhorse (balanced performance)

35kHz = precision tool (small + delicate parts)

15kHz is the “power platform.” It’s selected when your process needs more mechanical authority and higher energy delivery, especially on larger weld areas and thicker materials.

Choose 15kHz when:

A. The part is large (wide perimeter or large weld footprint)

B. Walls are thick and need high melt volume

C. Weld strength requirements are high

D. Material is filled or stiff (ex: glass-filled nylon)

E. You want fast cycle times on high-energy joints

F. Horn area must be large

1) Maximum power and amplitude

15kHz systems typically offer higher power output and can run at higher amplitude, which helps create strong, fast welds in large parts.

2) Easier large-horn design

Lower frequencies support larger horns more easily. That matters when parts require wide contact surfaces, deep reach, or custom tooling.

3) Strong for thick parts and high stiffness plastics

When parts absorb energy or require greater melt volume, 15kHz can stabilize the process.

A. More audible noise (15kHz is near the upper range of human hearing)

B. Higher amplitude can increase: surface marking, flash, stress cracking on brittle parts

C. Not ideal for very small or delicate assemblies

a. Large housings and structural components

b. Automotive interior/under-hood parts

c. Thick-wall assemblies

d. Large nonwoven bonding

e. High-strength industrial parts

Recommend 15kHz machine welding system: Pneumatic Precision Welder

If you had to pick one frequency as the default for plastic welding, it’s 20kHz.

Choose 20kHz when:

1. Your part is medium-size (most consumer and industrial parts)

2.You need balanced power and control

3.You want proven processes and easy tooling availability

4.You’re launching a new product and want a safer starting point

5.You need flexibility across multiple products

1) Best balance of power and precision

20kHz performs well across a wide range of geometries, materials, and joint types.

2) Most common platform

Because it’s widely used, tooling vendors and welding suppliers have more standard solutions available. This often reduces lead times and costs.

3) Wide process window

20kHz often provides a forgiving combination of amplitude range and power output, helping with part-to-part variation.

a. Not as powerful as 15kHz for the largest, highest-energy parts

b. Not as gentle as 35kHz for micro assemblies and thin walls

a. Consumer product enclosures

b. Appliance and packaging components

c. Automotive clips, caps, housings

d. Moderate-size medical disposables

e. General staking and insertion

Recommend 15kHz machine welding system: Servo Ultrasonic Welder

35kHz is commonly chosen when a part is small, thin, or requires excellent cosmetic appearance.

Choose 35kHz when:

a. Your parts are small or have micro features

b. Wall thickness is thin and sensitive to deformation

c. You need minimal stress and minimal marking

d. Cosmetic finish is critical (glossy surfaces, visible zones)

e. You’re welding delicate medical or electronic components

1) Lower part stress

Higher frequency welding typically operates at lower amplitude, meaning less mechanical “shock” transmitted to the part. This reduces cracking and deformation.

2) Cleaner cosmetics

35kHz is excellent when you must avoid:, horn witness marks, whitening, sink marks, flash around the joint.

3) Great for micro-feature repeatability

Small contact areas benefit from higher frequency stability and precise energy delivery.

A. Lower power availability than 15kHz/20kHz

B. Horns must be smaller and are often more specialized

C. Can struggle with large perimeter joints or thick sections

D. Process may be less tolerant of misalignment or part variation

A. Medical disposables and diagnostic components

B. Microfluidic assemblies

C. Small caps, filters, and connectors

D. Electronics and sensor housings

E. Thin-wall cosmetic parts

Recommend 35kHz machine welding system: 35Khz 800W Ultrasonic Welding System

Here are practical selection rules that work well in real production settings:

A. Large parts → 15kHz

B. Medium parts → 20kHz

C. Small parts → 35kHz

If you’re seeing: cracking , whitening , deformation , flash that won’t go away …moving toward 35kHz can help.

If you’re seeing: weak welds , long weld times , inconsistent energy delivery, incomplete melt on thick sections

…moving toward 15kHz (or from 35 → 20) can help.

If you need a large horn face, long reach, or complex horn geometry, 15kHz or 20kHz is usually more practical.

✅ Try 35kHz

Also reduce amplitude, pressure, and optimize joint design.

✅ Try 15kHz

Also increase energy director size or use a shear joint.

✅ Try 35kHz

Also improve horn finish and reduce amplitude.

✅ 20kHz often gives the best tolerance window

Also improve fixturing and consider collapse distance control.

✅ Often joint design, but 35kHz can reduce aggression

Also reduce amplitude and verify alignment.

Even the “perfect” frequency won’t save a poor setup. For consistent ultrasonic welding, focus on:

A. Joint design (energy director, shear joint, tongue-and-groove)

B. Rigid, repeatable fixturing

C. Proper clamp force

D. Correct amplitude and weld mode : time / energy / peak power/ collapse distance

Tooling quality (horn material, surface finish, tuning)

Most welding issues blamed on frequency are actually joint design or fixture stability problems—so make sure those are solid before switching platforms.

20kHz is the most widely used and works for the broadest range of applications. It’s typically the best starting point unless your part is unusually large (15kHz) or very small/delicate (35kHz).

Often yes, especially for small parts. But cosmetics depend heavily on horn finish, joint design, and clamp force. A properly optimized 20kHz process can still produce excellent cosmetics.

15kHz is closer to human hearing range. Even when the welding frequency itself isn’t clearly audible, harmonics and mechanical resonances often create more audible noise.

Sometimes. But horn design, amplitude range, and power delivery change significantly. A part optimized for 35kHz may not transfer directly to 15kHz without redesigning the joint and tooling.

To choose the right ultrasonic welding frequency, match the system’s behavior to your part:

A. 15kHz is best for large, thick, high-energy welds that require maximum power and big tooling.

B. 20kHz is the most versatile, delivering excellent results for the majority of plastic welding applications.

C. 35kHz is the best fit for small, delicate, thin-wall, and cosmetic-critical parts, where precision and low stress matter most.

If you’re unsure, start with 20kHz—then move to 15kHz for bigger power needs or 35kHz for higher precision and better cosmetics.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107

We chat