In ultrasonic plastic welding, a joint that looks good isn’t always a joint that seals well.

Many production teams experience the same frustrating scenario: the weld line appears uniform,

pull strength meets spec, and the cycle time is stable—but the part fails the leak test (pressure decay,

bubble test, or helium leak detection).

Leak failures rarely come from a single factor. In most cases, they are the result of combined effects

from part design, material behavior, process settings, tooling/fixturing, and even the test method itself.

This article provides a practical, engineering-focused breakdown of the most common causes and the

most effective solutions—plus a step-by-step troubleshooting roadmap you can use on the factory floor.

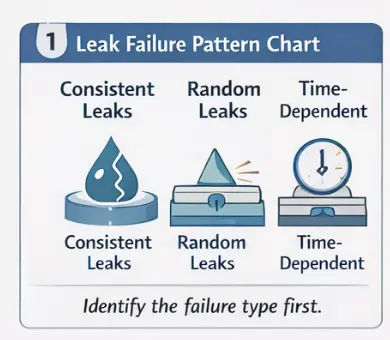

1) First: Identify the Leak Failure Pattern (This Saves Hours)

Before changing parameters, classify the failure. Different failure patterns usually point to different root causes:

A. Consistent leak failure (almost every part fails)

Typical cause: insufficient melt or incomplete fusion, often driven by joint design, horn contact,

or low energy transfer.

B. Random leak failure (some pass, some fail)

Typical cause: variation—part fit-up, fixture repeatability, dimensional tolerance stack-up, or

inconsistent clamping.

C. Time-dependent leak failure (passes now, fails later)

Typical cause: residual stress, micro-cracks, creep relaxation, or seal deformation after cooling/aging.

Why this matters:

If you don’t know which pattern you’re dealing with, you’ll chase symptoms with parameter tweaks

and never stabilize the process.

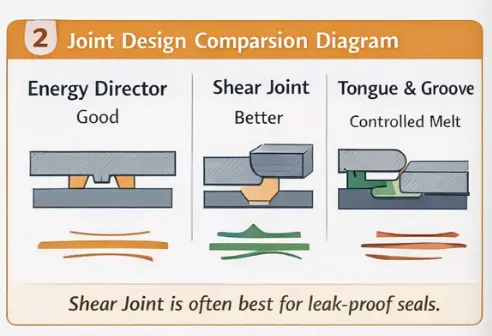

2) Root Cause Category #1 — Joint Design Issues (Most Common)

Even with a perfect machine, the joint must be designed to create controlled melt flow

and form a continuous sealing ring.

Common design-related leak causes include:

Cause 1: Energy director too small / discontinuous

If the energy director is undersized or interrupted, the joint may “stick” in spots but never

build a continuous hermetic seal.

✅ Solutions

Increase energy director height and angle (within material limits)

Ensure a continuous sealing path (avoid breaks in the perimeter)

Use a shear joint for demanding leak requirements (better melt containment)

Cause 2: No controlled melt containment (flash becomes a leak path)

If molten plastic is forced outward or inward unpredictably, it can form voids, channels, or

inconsistent collapse—leading to leaks.

✅ Solutions

Add a flash trap / overflow groove

Use tongue-and-groove features to control flow

Balance wall thickness to prevent differential melt

Cause 3: Weld line too close to ribs, bosses, or snap features

Nearby structures can pull heat away, deform during welding, or cause local stress concentration.

✅ Solutions

Increase distance between seal line and structural features

Add local stiffening under the joint to reduce flex

Redesign ribs to avoid “hinge” movement

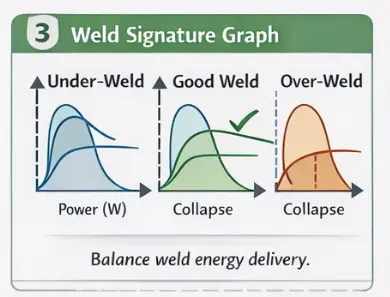

3) Root Cause Category #2 — Process Settings (Energy Delivery Problems)

When leak failures occur, many teams raise weld time and pressure first. That often makes things worse—

by creating stress cracks, marking, or flash. Instead, focus on how energy is delivered.

Cause 4: Under-weld (insufficient melt / incomplete fusion)

Parts may look fused, but micro gaps remain.

✅ Solutions

Increase amplitude (more effective than time alone)

Switch to energy mode or collapse distance mode for repeatability

Add hold time to stabilize the seal while cooling

Check stack tuning and horn-face contact

Cause 5: Over-weld (excessive melt → voids and seal collapse)

Too much energy can squeeze out molten material, trap bubbles, or create weld-line thinning.

✅ Solutions

Reduce amplitude, especially on thin walls

Use collapse distance limits to prevent over-collapse

Reduce pressure if it is forcing melt out too aggressively

Optimize trigger force to ensure consistent start

Cause 6: Inconsistent collapse (random leak failures)

If your collapse varies part-to-part, your seal continuity will vary too.

✅ Solutions

Use collapse distance control with strict limits

Improve fixture rigidity and part seating

Monitor peak power and collapse signatures for drift

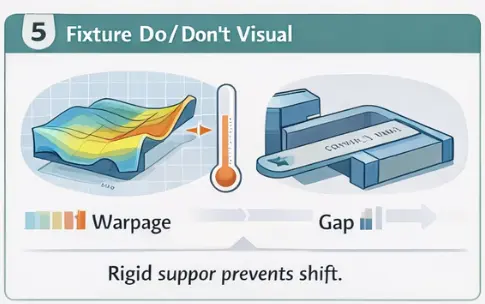

4) Root Cause Category #3 — Fixturing & Alignment (The Hidden Leak Generator)

Fixturing issues cause more random leak failures than most teams realize.

Cause 7: Part rocking or incomplete seating

If the part tilts slightly, the horn may weld one side more than the other, leaving micro gaps.

✅ Solutions

Add locating features that constrain all axes

Increase fixture support directly under the seal line

Use vacuum or nest inserts to prevent tilt

Cause 8: Horn misalignment or uneven contact pressure

Even slight angular misalignment can create uneven energy distribution.

✅ Solutions

Verify horn parallelism and face flatness

Use carbon paper or pressure-sensitive film to check contact uniformity

Ensure horn/fixture rigidity; eliminate flex under load

5) Root Cause Category #4 — Material & Molding Variation

Sometimes the welding process is fine—the parts are not.

Cause 9: Moisture, contamination, mold release residue

Moisture can cause bubbling; mold release can prevent wetting and fusion.

✅ Solutions

Dry hygroscopic materials (PA, PC, PET, etc.) to spec

Ban mold release on sealing surfaces (or strictly control type and application)

Improve handling to avoid oil/dust contamination

Cause 10: Warpage / shrink variation → poor fit-up

Leak tests fail when the joint line has gaps before welding.

✅ Solutions

Improve molding process control (pack/hold, cooling balance)

Add design features for self-alignment

Tighten tolerances around seal line

Measure pre-weld gap using gauges or 3D scans

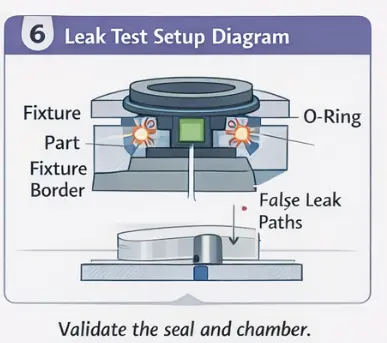

6) Root Cause Category #5 — Leak Test Method Errors (Yes, the Test Can Lie)

Leak test failures sometimes come from the test, not the weld.

Cause 11: Wrong test pressure / stabilization time

Pressure decay tests can fail if the part expands, temperature changes, or the stabilization time is too short.

✅ Solutions

Add stabilization time before measurement

Control test temperature (plastic expands with heat)

Set pressure based on part stiffness and design

Calibrate decay thresholds against known-good samples

Cause 12: Fixture sealing leaks during test

If the test fixture O-ring leaks or seats inconsistently, good parts may fail.

✅ Solutions

Validate the fixture with a solid reference plug

Replace O-rings on schedule

Use consistent clamp force and alignment for testing

7) A Practical Troubleshooting Roadmap (Use This on the Shop Floor)

Here’s a fast, systematic approach that avoids guesswork:

Step 1: Confirm the failure pattern

Consistent / Random / Time-dependent?

Step 2: Locate the leak path

Bubble test to identify location

Helium sniffing for precision

Dye penetration (where applicable)

Step 3: Compare weld signatures

Look at:

peak power

energy

collapse distance

cycle time

hold phase stability

A good process leaves a consistent “fingerprint.”

Step 4: Validate fixture rigidity and alignment

If random failures exist, suspect the nest.

Step 5: Adjust the right knob

Under-weld → increase amplitude or energy

Over-weld → cap collapse distance, reduce amplitude

Random leaks → fix seating + alignment, then tune

Final Takeaway: Hermetic Success is a System, Not a Setting

Ultrasonic leak failures are almost never solved by “just increasing weld time.” The most reliable

approach is to treat the seal as a system:

Design for controlled melt flow

Deliver energy consistently

Clamp and locate parts rigidly

Control material and molding variation

Validate the leak test fixture and method

When these five pillars are aligned, leak performance becomes repeatable—

high yield, stable process, and fewer surprises.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107