1.Fully automation loading, ultrasonic welding and unloading.

2. Brands components like Allen Bradley PLC and HIM,SMC pneumatic parts,etc.

3.High efficiency and production.

4.Interlock system to ensure safety operation.

We build custom automation lines from concept to mass production, integrating ultrasonic welding, laser marking, leak testing, vision inspection, and MES connectivity.

Typical line formats: rotary multi-station, inline conveyor, or modular work-cell.

Key benefits:

• High throughput with stable yield

• Process traceability & intelligent control

• Fast fixture change and scalable modules

How to Start

Send us your part + target cycle time + quality requirement.

We will propose a line concept and key-station selection within 24h.

Application

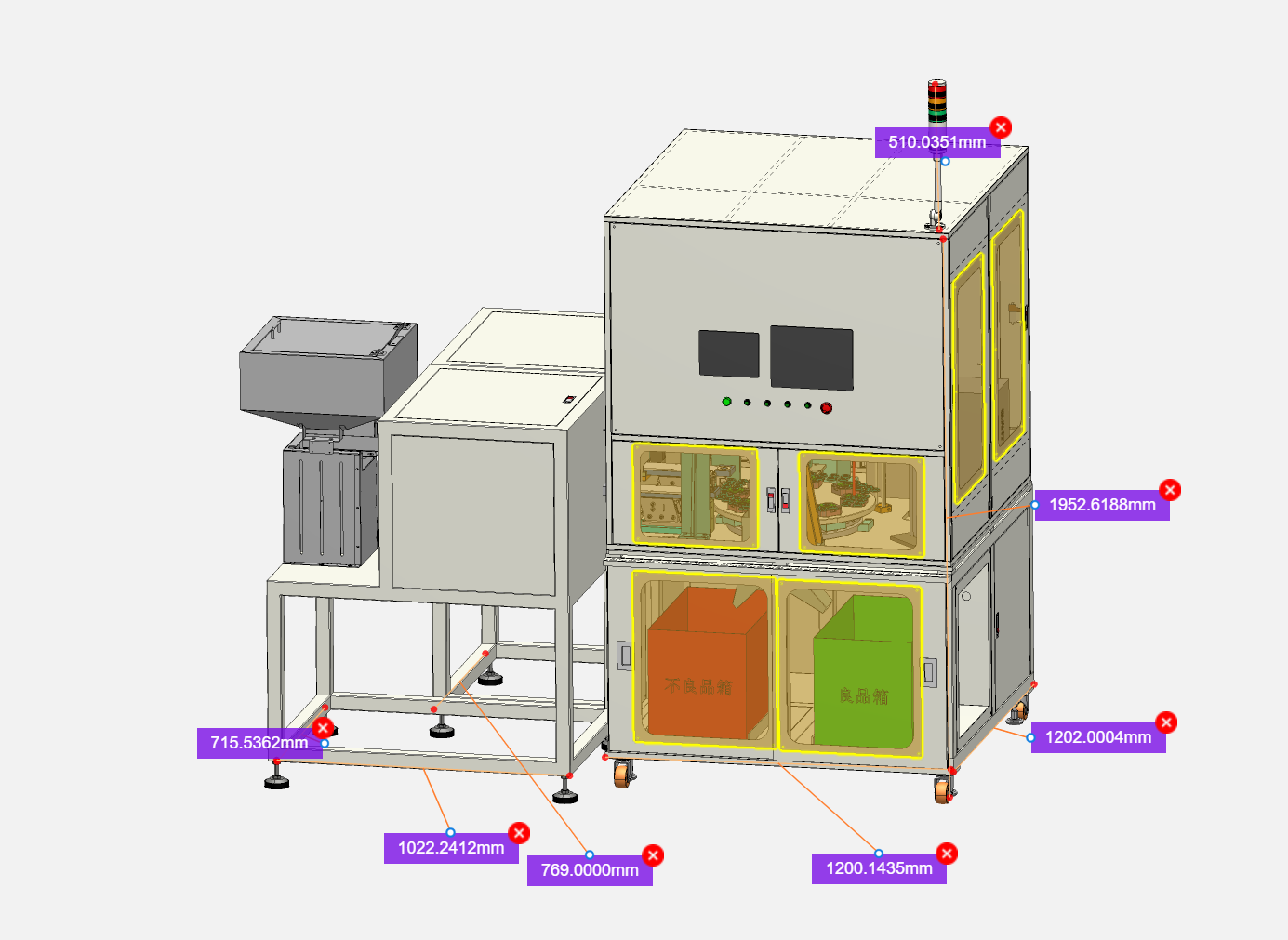

Automaiton Ultrasonic Welding and Laser Marking Machine is combined with ultrasonic welding and laser marking

under automation operation. The machine is used for welding plastic parts and non-woven felt. At the same time,

the machine system also support laser marking function for serial number or letters printing on plastic parts.

Fully automation operation and eco-friendly operation.

High quality main compoments ensure smoothly running and stability.

Productivity and low malfunction rate.

Keyence Vision System ensure precision inspection result.

AB PLC and HIM ensure operation system.

Titanium alloy welding head ensure durability.

Eight workpiece position highly improve production.

Slewing bearing support rotary station.

Machine Dimension: 3350*850*1950mm(not include top Buzzer)

Machine Weight: approx. 1208KG

Supply Power: 220V 50Hz Single Phase ( customization)

PLC: AB(Allen-Bradley)

HIM: AB(Allen-Bradley)

Power: Schneider

Vision System: Keyence 2D vision system

Ultrasonic Frequency: 20Khz

Ultrasonic Power: max 2600W

Work Mode: Automation

Workpiece: 8 work stations

Vibration Bowl Feeder: 2 sets (customization)

Hopper: 1set

Laser Marking System: 1set

Cylinders: SMC

Welding Head: Titanium Alloy (optional aluminum alloy)

Compliance to Solid Wood Packaging Materials (SWPM) Regulations: The International Plant Protection

Convention(IPPC) and International Standards for Phytosanitary Measures no. 15 (ISPM's #15) guidelines

protect against insect infestation in packaging materials.

Warranty

Machine (except consumable parts like sensors) is one year warranty under normal operation,lifetime technical support

and service. Machine parts defect during warranty period, which will be sent to your end for replacement.

After-sale Service

If need any technical support,kindly contact us lively video call, phone call or email. email or phone call.

Oversea onsite service(optional): mutual communication for detail discussion.There could be extra fee(like travelling fee,

insurance,commodity fee,etc.) result from the traveling.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107

We chat