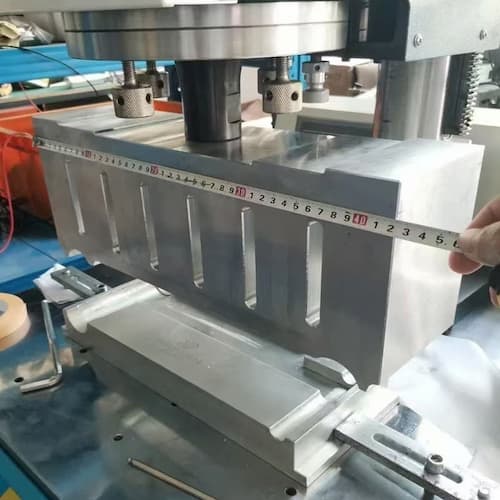

High-precision ultrasonic welding molding horns designed for stable energy transmission and consistent welding performance.

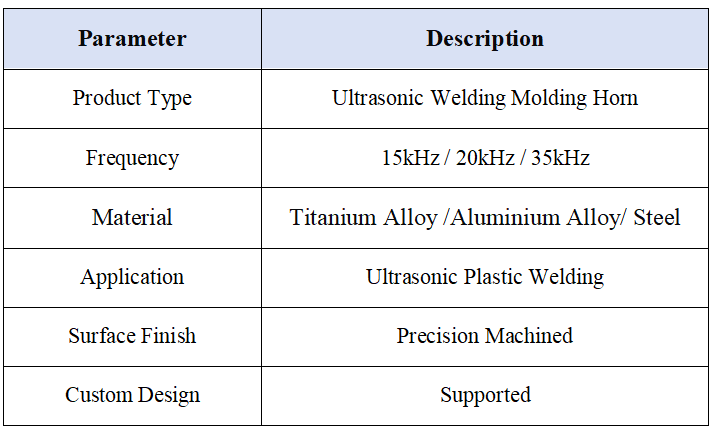

Available in 15kHz, 20kHz, and 35kHz frequencies, suitable for a wide range of ultrasonic welding systems and custom automation solutions.

Ultrasonic welding molding horns are critical components for transmitting ultrasonic vibration energy during

plastic welding processes.

Timeast TEC provides precision-engineered ultrasonic molding horns in 15kHz, 20kHz, and 35kHz, designed

for stable vibration performance, high durability, and compatibility with ultrasonic welding systems and custom

automation solutions.

Precision-machined for stable ultrasonic energy transmission

Optimized horn geometry for consistent plastic welding quality

High fatigue resistance for long-term industrial use

Compatible with ultrasonic welding machines and automation lines

Custom ultrasonic horn designs available upon request

Timeast TEC ultrasonic welding molding horns are available in multiple operating frequencies to meet

different welding requirements:

15kHz ultrasonic molding horns – Suitable for large welding areas and high-power plastic welding applications

20kHz ultrasonic molding horns – Standard frequency widely used in general ultrasonic plastic welding

35kHz ultrasonic molding horns – Ideal for small parts, thin-wall components, and precision welding

Our ultrasonic molding horns are manufactured from high-quality materials such as titanium alloy and

hardened steel, offering excellent vibration transmission, wear resistance, and service life.

Each horn is precisely machined and frequency-tuned to ensure stable resonance and reliable welding

performance in ultrasonic plastic welding systems.

Automotive plastic components

Electronic and electrical plastic parts

Medical device components

Packaging products

Consumer plastic products

Timeast TEC offers custom ultrasonic welding molding horn solutions based on customer part design,

material type, welding area, and production requirements.

Our engineering team supports customers from design optimization to final testing, ensuring optimal

ultrasonic welding performance for each application.

Professional manufacturer of ultrasonic welding systems

In-house design, machining, and quality control

Experience in custom automation solutions

Reliable products for industrial production lines

Looking for reliable ultrasonic welding molding horns for your application?

Contact Timeast TEC today to discuss your requirements or request a quotation.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107