Industrial servo driven heat staking machine for precision hot press and plastic assembly with controlled stroke and force. Ideal for automotive, electronics, and precision components manufacturing.

The High Precision Servo Driven Heat Staking Machine is a versatile industrial hot press designed for

precise and repeatable heat staking, thermal joining, and plastic assembly applications.

Driven by a high-precision servo electric cylinder, this machine delivers controlled pressure and accurate

stroke for consistent production results in demanding manufacturing environments.

This machine is ideal for factories that require stable, programmable, and repeatable heat press processes in

automotive trim fabrication, consumer electronics, plastic fastening, and precision component assembly.

Servo Driven Control System — High accuracy and closed-loop position/force feedback

Programmable Multi-Stage Stroke — Customizable press profiles for varied materials

Touchscreen Operation Interface — Intuitive parameter setting and monitoring

Compact & Robust Industrial Design — Built for continuous production

Precise Temperature & Pressure Control — Reduces defects and improves assembly quality

The servo hot press utilizes a high-precision servo electric actuator to control the press head position,

speed, and force.

By applying controlled heat and pressure, the machine enables:

Plastic component staking and deformation

Thermal fastening of plastic inserts

Heat form shaping of plastic parts

Controlled softening and bonding of material interfaces

This method ensures repeatable, low-variance results compared to traditional pneumatic or mechanical

press systems.

This servo heat staking machine is widely used for:

Automotive interior plastic assembly

Electronic enclosure assembly

Plastic fastener staking

Precision plastic part joining

Industrial components requiring controlled thermal pressing

Watch this machine in operation as it performs precision heat staking with controlled stroke and force.

This video shows how servo motion and heat are combined to achieve consistent, repeatable assembly performance.

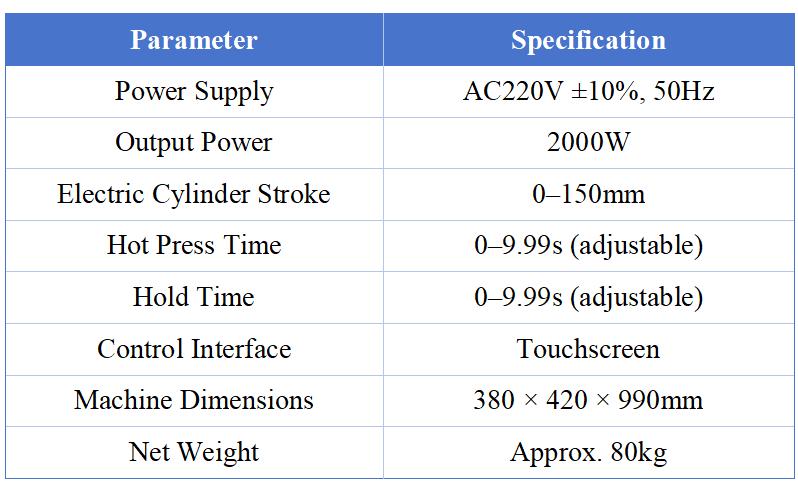

Specifications can be customized for specific applications on request.

This heat staking machine can be integrated with upstream or downstream automation systems, including:

Part feeders and conveyors

Vision inspection and alignment systems

MES connectivity

Safety light curtains and interlocks

Pre-sales application analysis

Installation and operation training

One-year warranty with lifetime technical support

Fast spare parts delivery

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107