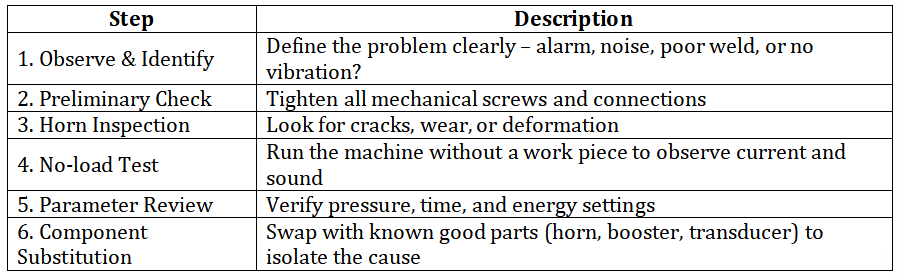

Ultrasonic welding is one of the most efficient and reliable methods for joining thermoplastics and metals.

However, even with advanced equipment, problems such as poor weld strength, noise, or overheating

can occur—impacting product quality and production efficiency. This guide will help you identify, diagnose,

and fix the most common ultrasonic welding issues, ensuring your production line stays stable and efficient.

Possible Causes:

• Damaged or poor-quality horn material

• Inaccurate horn design leading to vibration imbalance

• Degraded transducer performance (increased impedance)

• Internal cracks or poor acoustic transmission

Solutions:

• Replace with a qualified horn; temperature should not exceed 50–70℃ after 30 minutes of no-load operation

• Ensure symmetrical design and CNC precision machining

• Contact the manufacturer to test or replace the transducer

• Use the “hand-touch” test to check for uneven surface amplitude

Possible Causes:

• Loose installation screws

• Cracked horn

• Horn contacting foreign objects

Solutions:

• Tighten all mounting screws

• Replace cracked horns immediately

• Ensure the horn has sufficient clearance and no external contact

Possible Causes:

• Horn contacting external parts

• Faulty horn, booster, or transducer

• Generator malfunction

Solutions:

• Conduct a no-load test – if current is normal, inspect for interference or misaligned parameters

• Troubleshoot step by step: horn → booster → transducer

• Test with verified components to confirm if the generator is defective

Possible Causes:

• Mechanical: Worn guide rails, loose bolts, failed buffer pads

• Pneumatic: Unstable air pressure, aging seals, incorrect throttle adjustment

• Control: Excessive welding pressure, PLC delay, sensor malfunction

Solutions:

• Replace worn mechanical parts and tighten fasteners

• Stabilize air supply and replace old seals

• Optimize welding pressure and verify PLC signal timing

Possible Causes:

• Amplitude mismatch (like incorrect “temperature”)

• Incorrect parameter settings (time, pressure, or power)

• Fixture misalignment or insufficient support

Solutions:

• Calibrate horn and booster to ensure proper amplitude (~30μm typical)

• Optimize welding time, pressure, and power systematically

• Recheck fixture alignment and holding stability

Amplitude — The key performance parameter, analogous to temperature in traditional welding.

Too low → weak welds. Too high → material damage or horn fatigue.

Frequency — Each welder operates at a specific frequency (e.g., 15kHz, 20kHz, 40kHz).

If the generator and acoustic stack are out of tune, resonance fails, causing overload or low amplitude output.

Horn Design — The horn is a half-wavelength resonant body. Material (titanium or aluminum) and

machining precision directly affect performance. Asymmetry or poor machining causes heating,

imbalance, and cracks.

• Keep all components (guide rails, sensors) clean and dust-free

• Check air pressure stability and seal integrity

• Tighten all mechanical fasteners periodically

• Record every failure and repair for trend analysis

• Create a scheduled maintenance program for key components

• Train operators in basic troubleshooting and equipment handling

Ultrasonic welding success depends on balanced amplitude, frequency, and mechanical precision.

Always troubleshoot systematically—from simple mechanical checks to advanced acoustic analysis.

Preventive maintenance dramatically reduces downtime.

Keep detailed records and consult the manufacturer when unusual issues occur.

Effective ultrasonic welding troubleshooting combines technical knowledge, systematic diagnosis, and preventive discipline. By following the structured approach in this guide, you can minimize production downtime, ensure consistent welding quality, and extend equipment lifespan. If persistent or complex issues occur, always consult your equipment manufacturer or a certified ultrasonic technician for expert assistance.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107

We chat