The ultrasonic wire harness welding machine is used to weld wire harnesses ranging from 0.3mm² to 50mm² in size.

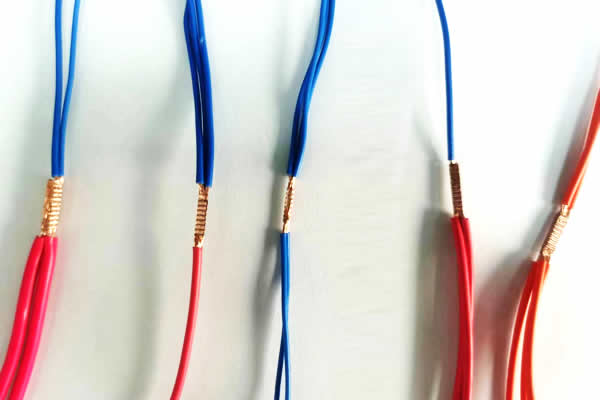

It is primarily applied in various fields such as automotive wire harness splicing, wire end forming, wire mutual

welding, and joining multiple wires into a single structure.

The ultrasonic wire harness welding machine is suitable for materials including copper-aluminum wire harnesses,

metal braided wires, metal stranded wires, wire harness terminals, enameled wires, motor lead-out wires, and

copper wires for welding purposes. It finds extensive use in industries such as automotive, electronics, electrical

appliances, motors, communication equipment, machinery, and instrumentation.

Welding Characteristics of Ultrasonic Wire Harness Welding Machine:

The machine's power ranges from 3000W to 4000W. It can achieve one-time welding and forming of wire harness

sections ranging from 0.35mm² to 28mm² (we are continuously developing machines to weld larger square-section

wire harnesses).

The machine features an integrated design with advanced structure, compact size, lightweight, and attractive

appearance, making it easy to move.It enables cost-effective wire harness splicing, resulting in good conductivity,

extremely low or nearly zero resistance, short welding times, and requires no flux, gas, or welding materials.

This welding process is environmentally friendly and represents an advanced electrical splicing technique.

As known, ultrasonic welding is widely used in wire harness processing and is a significant manufacturing

technique. Ultrasonic metal welding technology is commonly applied in low-voltage and communication

wire harness welding in the automotive industry. Due to the growing demand in the electric vehicle industry,

high-voltage wire applications have become essential. Many advanced technologies are gradually replacing

crimping with ultrasonic welding, becoming one of the more stable and safer welding processes.

In the ultrasonic metal welding process, high-frequency vibration is applied to heat metal molecules, causing

them to separate and form new grains (metal molecular fusion). Since no molecular damage occurs, the joint

is fused without compromising the physical strength, resulting in a joint strength close to the product's inherent

strength. This method is particularly suitable for welding non-ferrous metals and even dissimilar metals.

With the increasing trend toward electric vehicle electrification and safety requirements, the demand for electrical

performance in wire harness connections is rising. Ultrasonic welding offers advantages such as lower resistance,

higher strength, safer and more environmentally friendly conductivity. As a result, it is being widely adopted across industries.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107